The primary ports of a muzzle brake are designed to direct gases horizontally (as opposed to vertically or aimlessly). The ports may not be horizontal when you attach them to a threaded barrel. To ensure that they are properly aligned, you’ll need a package of shims to time the brake.

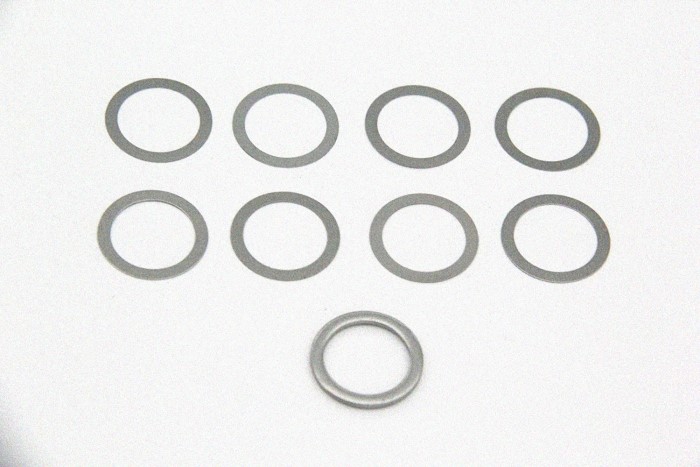

Shims are pieces of metal that allow you to align a muzzle device correctly by filling any gaps between the two. You can find these in different thicknesses and sizes, sold in packages. Sometimes they have markings on them to determine the thickness.

Here are a few general tips:

1) Start by measuring the distance from the barrel’s crown to the front edge of the muzzle brake. This will give you a baseline measurement that you can use to compare against future measurements.

2) Use a shim of an appropriate thickness (depending on how much you need to adjust the alignment) and place it between the brake and barrel.

3) Screw the muzzle brake onto the barrel until it is tight.

4) Take another measurement from crown to brake edge and compare it to your baseline measurement. If necessary, add or remove shims until the two measurements match.

5) Once you’re satisfied with the alignment, you can secure the muzzle brake in place with set screws or thread locker.

Self-timing muzzle brake allows the user to install it and lock down the collar so it times on the barrel exactly the same way every time it’s installed.

The most detailed video for you to leave no doubt:

Muzzle brake timing is a process of finding the “sweet spot” where tightened down muzzle brake have the ports line up to the sides. This is typically done by placing shims between the brake and barrel to adjust the position of the brake.

There is no one-size-fits-all answer to this question, as each muzzle brake will have different timing. However, there are some general tips to help you time your muzzle brake:

1. Start with no shims and screw your muzzle brake onto the barrel. Then tighten it to manufacturer specification, using a torque wrench.

2. Make a note of how the muzzle brake is facing in relation to where you ultimately want it positioned. Add shims until you think it will be placed properly after tightening.

3. Finish tightening your muzzle brake fully using a torque wrench.

It’s easy, but it will require a little precision on your part:

See also: the AmmoCave team picked up the best flash hiders for you!

There are a few different ways to time a muzzle brake. One way is to use the washers that come with the brake. Another way is to use a set of calipers to measure the distance between the brake and the barrel, and then add or subtract shims as needed to get the brake in the correct position.

Another option is to use an alignment rod. This is a piece of metal or plastic that is inserted down the barrel and against the muzzle brake. The idea is that you adjust the position of the brake until it’s parallel with the rod. Once it’s in line, you can add or subtract shims as needed to keep it in position.

Whichever method you choose, the goal is to get the muzzle brake aligned so that it’s level with the barrel.

Keep in mind that it’s important to be as precise. A small mistake can result in increased recoil and make your gun more difficult to control. If you’re unsure of your ability to do this correctly, it’s best to consult a professional gunsmith.

You can time a muzzle brake with shims or a crush washer. While a crush washer is unreliable because it bends unevenly, shims are easy to use and come in different sizes for fine-tuning.

The right way to do it is to tighten the muzzle brake and observe its position, thinking about how many shims you can add to set your muzzle brake in a 12 o’clock position, where all the holes are set horizontally. Then reinstall the muzzle brake adding shims and tighten it down. Ensure that the muzzle brake is centered on the barrel.

Picture a clock. Timing the brake is adjusting the shoulder by removing small increments until the slots on the brake are “timed” at 3:00 and 9:00 (for brakes with opposing slots only) when it is torqued in place.

Once you have the brake, use shims or a crush washer to adjust the muzzle brake position till the holes are perfectly aligned to where they’re supposed to.