Affiliate Disclosure: AmmoCave.com sometimes gets paid for listings, through sponsors or affiliate programs like Lucky Gunner, Optics Planet, Brownells, Cabelas, Academy Sports & Outdoors, Rainier Arms, Palmetto State Armory, Sportsman’s Guide, Ammo.com, Ammo Man, Primary Arms, MidWayUsa, Amazon, eBay, etс. Clicking a link helps keep AmmoCave.com free, at no extra cost to you!

Authors: Each article is verified by AmmoCave's expert team. Professional hunters, firearm trainers, gunsmiths, and gun experts write the articles. AmmoCave Team independently researches, tests, reviews, and uses recommendations from our community of gun owners. We may earn commissions from shopping links.

Note: The views and opinions expressed in this article are those of the authors and do not necessarily reflect any agency's official policy or position. The articles are for informational purposes only, share your opinions about Best Nickel Boron BCG 2026 in the comments and join the discussions. Let's share 💬 our ammo & gun experiences together!

What is Nickel Boron BCG? 💡

It is a type of coating used on the bolt carrier group of a rifle. This coating is made up of a combination of nickel and boron that is applied to the steel carrier using a process called electroless plating. The resulting coating is incredibly hard and durable, making it an ideal choice for those who demand high performance and reliability from their firearms.

Features 📢

🌐 1. Corrosion Resistance: They are coated with a thin layer of nickel boron, which provides excellent corrosion resistance, making them ideal for use in harsh environments.

🌐 2. Self-Lubricating: The nickel boron coating on the BCG creates a self-lubricating surface that requires minimal oil for smooth operation.

🌐 3. Durability: They are known for their exceptional durability due to their hard, wear-resistant coating.

🌐 4. Easy to Clean: The slick surface of the nickel boron coating makes it easy to clean the BCG, reducing maintenance time and costs.

🌐 5. Improved Functionality: The slick surface of the nickel boron coating makes the BCG slide more smoothly, reducing friction and improving overall functionality.

🌐 6. Enhanced Reliability: Nickel Boron bolt carrier groups have been shown to increase the reliability and longevity of firearms due to their durability and corrosion resistance.

🌐 7. Lighter Weight: They are usually lighter than traditional BCGs, making them a great choice for those looking to reduce the overall weight of their firearm.

🌐 8. Improved Appearance: The nickel boron coating provides a unique, attractive appearance that is often preferred by gun enthusiasts.

🌐 9. Consistency: They are manufactured with precision and consistency, ensuring reliable operation and consistent performance.

🌐 10. Compatibility: They are compatible with a wide variety of firearms, making them a desirable upgrade for many gun owners.

Watch this video to find more information 💻

Components 🧩

🎯 1. Bolt:

- It is responsible for locking the cartridge into place, initiating firing, extracting spent cartridges from the chamber, and ejecting them from the rifle.

- The bolt typically has three parts- the bolt body, the firing pin, and the extractor.

🎯 2. Carrier:

- The carrier is part of the BCG that holds the bolt and facilitates its movement within the rifle.

- The carrier also houses the gas key that connects to the gas tube and receives the gas that propels the bolt rearward.

🎯 3. Gas Key:

- The gas key is a small piece of metal that attaches to the top of the carrier and is responsible for directing gas from the barrel back into the carrier to cycle the bolt.

- This component is integral to the operation of the BCG.

🎯 4. Cam Pin:

- The cam pin is a small pin that fits into the bolt and is responsible for rotating the bolt as it moves back and forth through the carrier.

- This rotation helps to lock the bolt in place and prevent unwanted movement.

🎯 5. Firing Pin:

- The firing pin is the component responsible for striking the primer of the cartridge, initiating the firing process.

- It is a small, needle-like part that protrudes from the back of the bolt.

🎯 6. Extractor:

- The extractor is responsible for removing spent cartridges from the rifle after they are fired.

- It does so by gripping the rim of the cartridge and pulling it from the chamber as the bolt moves rearward.

Best Nickel Boron BCG 🚀

1# Phase 5 Weapon Systems Bolt Carrier Group

The Phase 5 Weapon Systems Bolt Carrier Group is the perfect upgrade for your AR-15. As our tests have shown the coating on the bolt carrier group enhances reliability and minimizes required bolt lubrication. The Hardened gas key and grade 8 hardened fasteners provide a durable, long-lasting option for your AR-15.

2# Lantac Enhanced Full Auto Style Bolt Carrier Group

Looking for a top-quality Bolt Carrier Group for your auto rifle? Then check out the Lantac Enhanced Full Auto Style Bolt Carrier Group with NiB Coating! This BCG is precision machined from high-quality 8620 steel and coated with NiB electroless nickel boron, for superior durability and lubricity. It features a unique shape with forward porting that allows the upper receiver to run with less pressurization and runs cooler and cleaner with a flatter energy pulse. So don’t settle for anything less than the best – order the Lantac Enhanced Full Auto Style Bolt Carrier Group today!

3# Aero Precision Bolt Carrier Group

When you buy an Aero Precision Bolt Carrier Group, you’re getting a quality product that will function smoothly and effectively. The Aero Precision 5.56 Complete BCG features military specifications (mil-spec), including the gas key and extractor spring. Also, in the carrier itself, Aero machined forward assist serrations. With all of these high-quality features, you can rest assured that this bolt carrier group will serve you well for many years to come!

4# Spikes Tactical Bolt Carrier Group

The Spikes Tactical 308 Bolt Carrier Group is perfect for completing your build. This premium BCG features a phosphate or nickel boron finish and is made from tough tool steel. The gas key and extractor are also made from durable tool steel, so you can trust this BCG to withstand years of heavy use. The chrome interior of the carrier and gas key will hold up to tough conditions, making this an excellent choice for your next build.

5# Dark Storm Industries Bolt Carrier Group

The Dark Storm Industries Bolt Carrier Group is made from steel and is finished with a phosphate coating. This makes it extremely durable and resistant to wear and tear. The bolt itself is made from Carpenter Chromoly steel and is heat treated for added durability. This bolt carrier group is a great choice for any AR-15 owner looking for a high-quality, durable, and reliable product.

6# FailZero Bolt Carrier Group

If you’re looking for a top-of-the-line bolt carrier group that will improve the performance of your rifle, look no further than the FailZero M16/M4 Bolt Carrier Group. This BCG is treated with an EXO Nickel Boron coating that creates permanent dry lubricity, reducing friction and enhancing both the strength and corrosion resistance of the parts. With its easy drop-in installation on most Mil-Spec upper receivers, this is a great choice for anyone looking to get the most out of their rifle.

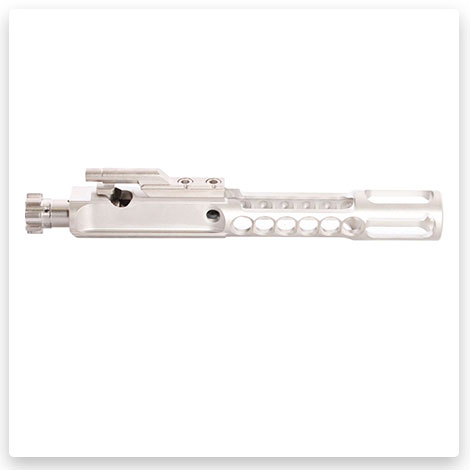

7# FosTech Outdoors Complete Lite Bolt Carrier Group

When you need a reliable and lightweight bolt carrier group for your AR-15, choose the FosTech Outdoors AR-15 Lite Bolt Carrier Group w/ Low Mass. These Bolt Carrier Groups by FosTech Outdoors are constructed out of nickel boron, ensuring the best quality and performance possible for your rifle. This Bolt Carrier Group has a Nickel Boron finish to reduce friction and resist wear, ensuring this part lasts through many years of use. Get the most out of your AR-15 with this high-quality bolt carrier group from FosTech Outdoors.

8# Black Rain Ordnance Bolt And Carrier Group Nickel Boron

The Black Rain Ordnance Bolt and Carrier Group are perfect for your next 308 build. The carrier is made from steel and features a black nitride finish, while the bolt is made from steel with a nickel boron coating for increased durability. The bolt also features an engraved Black Rain Ordnance biohazard logo on the spine. This bolt and carrier group is compatible with most 308 lowers on the market and is sure to give your build a unique look. Order yours today!

9# GUNTEC USA Mil-Spec Bolt Carrier Group

The Black Rain Ordnance Bolt and Carrier Group is a high-quality, durable piece that is perfect for anyone looking for a reliable product. Made from heavy-duty materials, this bolt carrier group will provide years of stability and dependability. It is also compatible with .308 Winchester cartridges, making it a versatile and convenient choice for many different applications.

10# F-1 Firearms Durabolt Bolt Carrier Group

Looking for an AR-10 bolt carrier group that is compatible with MIL-SPEC receivers and components? Look no further than the F-1 Firearms Durabolt 7.62 BCG. This direct impingement, full auto-rated bolt carrier group is enhanced with Chemical Vapor Deposition (CVD) technology for a durable, smooth action. The DuraBolt offers the lowest coefficient of friction on the market thanks to the micro-finishing process.

11# LBE Unlimited Nickel Boron Coated Bolt Carrier Group

If you’re looking for a top-quality bolt carrier group for your AR-15, look no further than the LBE Unlimited Nickel Boron Coated Bolt Carrier Group. This top-of-the-line BCG is constructed from steel and features a nickel boron finish that will provide exceptional durability and resistance to wear and tear. The bolt is made from steel for added strength and reliability, and the entire unit is designed to work with any AR-15 platform. Whether you want the best possible performance from their rifle, the LBE Unlimited Nickel Boron Coated Bolt Carrier Group is a perfect choice. Order yours today and see the difference quality makes.

12# WMD Guns Nickel Boron Bolt Carrier Groups

The WMD Guns bolt carrier group is made from high-grade steel alloy to government M16 specifications, then coated with WMD’s proprietary NiB-X nickel boron surface treatment. This results in an incredibly smooth, hard surface that is resistant to corrosion and abrasion. Our findings show that the slick finish also prevents carbon buildup, making cleaning quick and easy. You’ll appreciate the smoother cycling and improved performance that this bolt carrier group provides. Get your WMD Guns Nickel Boron bolt carrier group today!

13# WMD Guns Bolt Carrier Groups

Looking for a top-quality bolt carrier group that will give you an edge over the competition? Look no further than WMD’s Bolt Carrier Group. Precisely machined from high-grade steel alloy to government M16 specs, this BCG is given WMD’s proprietary NiB-X nickel boron coating. Don’t settle for anything less than the best – go with WMD’s Bolt Carrier Group!

14# Brownells Bolt Carrier Group Nickel Boron MP

The Brownells M16 5.56 Complete Bolt Carrier Group is fabricated from high-quality steel and features a heat-treated, shot-peened finish for durability and long-term performance. It is designed for use with all 5.56-NATO-based cartridge cases and is backed by the Brownells name, so you know you’re getting a quality product. Order yours today and be confident that your AR-15 or M16 will function flawlessly.

15# Brownells – 308AR Bolt Carrier Groups

The Brownells 308 AR Bolt Carrier Group is the perfect choice for your next big-bore rifle build. Reliable and durable, this BCG is designed to operate in DPMS LR-308. The bolt is machined from tough steel and heat-treated for exceptional hardness, while the carrier is fabricated from hardened steel. Both components are magnetic particle inspected (MPI) to ensure there are no hidden flaws that could lead to premature failure. After trying this product we noticed that this carrier also features forward assist notches, and the extractor is installed with a rubber insert and spring for added reliability.

16# Spikes Tactical Nickel Borron Bolt Carrier Group

If you’re looking for a top-quality bolt carrier group that will provide superb reliability in both semi-automatic and select-fire rifles, look no further than Spike’s Tactical Nickel Boron Bolt Carrier Group. The carrier is hard-chromed inside and the carrier key is fully staked and the extractor is made from tool steel for improved durability. Finally, the laser-engraved Spike’s Tactical logo on the side of the carrier is visible when the ejection port door is open, adding a nice touch of style.

17# Brownells Lightweight Bolt Carrier Group

Looking to improve your AR-15 without replacing major components or performing extensive gunsmithing work? The Brownells M16 Lightweight Bolt Carrier Group is designed for lightweight, low-recoil rifles and is a simple component swap that can make a big difference. This bolt carrier group is machined from tool steel and features a heavy-duty bolt made from tool steel, which has been magnetic-particle inspected for quality.

Cleaning 🧼

🧷 1. Disassemble the BCG: Start by disassembling the BCG to accessible parts. This will allow you to have a closer view of each component, making it easier to clean.

🧷 2. Use a cleaning solution: After disassembling, soak it in a cleaning solution such as Ballistol or Hoppes No. 9. These cleaning solvents aid in removing any dirt, debris, or fouling that may have accumulated.

🧷 3. Scrub the BCG: Use a toothbrush or other similar cleaning brush to scrub the BCG thoroughly. Because of our knowledge gained through practice, we recommend using a small pick to get into hard-to-reach areas. Be sure to clean every nook and cranny on the carrier and bolt.

🧷 4. Dry the BCG: After scrubbing, dry the BCG with a clean, dry cloth or compressed air. Ensure that all excess cleaning solvent and moisture are removed.

🧷 5. Reassemble the BCG: Once the BCG is dry, reassemble it and lubricate all moving parts to ensure optimal performance.

We believe this video can be helpful for you 📺

FAQ 😎

Conclusion🔔

When looking for the best nickel boron BCG, it is important to consider all of your needs and find the product that fits those needs. Our buyer’s guide can help you do just that. With in-depth reviews of some of the top nickel boron bolt carrier groups on the market, as well as tips on what to look for when making your purchase decision, we hope this guide will be helpful in finding the perfect product for your needs. Thank you for reading! ❤️ 🔥

Tags: #best nickel boron bcg / #best lube for nickel boron bcg / #best nickel boron bcg / #best ar 15 nickel boron bcg / #best way to clean nickel boron bcg

I’ve become a big fan of my NiB set and have even replaced the factory bolt carrier group (bcg) in my other rifles with it. The fact that it wipes (mostly) clean and can be run dry is great. However, I have noticed that running it dry can reduce the lifespan of the gas rings and cam pin, especially when using a suppressor. To counteract this, I recommend adding just a drop or two of lubricant to the rings and the cam pin shaft. This not only extends their lifespan but also makes cleaning a breeze (just wipe it down).

As with any coating, or plating, finish quality/smoothness is all in the surface prep prior to the application. Any brand preference(when it comes to mil spec) is purely personal experience/opinion. There are over 100 suppliers (just in the US) that produce the same exact “mil spec” parts for AR rifles, just like every other large industry.

re-write from the first person

Greetings. I am interested if nickel boron rust

Nickel Boron (NiB) is a corrosion-resistant coating that is commonly used in firearms. While it is highly resistant to corrosion, it is not completely immune to rust.

🔴 However, the likelihood of rust forming on a NiB-coated surface is significantly lower than with uncoated steel or other coatings that are less corrosion-resistant. It’s worth noting that regular maintenance and proper storage of firearms, including those with NiB coatings, can help prevent rust and other types of corrosion.

I happen to own one of the original Spikes Tactical Nickel Boron Bolt Carrier Groups (BCGs) from 2009, and I must say it’s been extremely reliable. I’ve fired thousands upon thousands of rounds through it and have only experienced one jam, which was a stovepipe. Although I still lubricate it as a habit, I don’t clean it as frequently as one might expect. However, I have noticed that over time, the bolt carrier group discolors and the bolt itself can become rough in areas where there’s no contact. Overall, my only gripe is with the discoloration, but the functionality and reliability of the NiB coating on this BCG have been impressive.

BCG Question: Which is better, Nickel Boron or Chrome plating? They both seem very similar with their slickness and low need for lubrication and easy cleaning. Is there a specific reason why one would choose one over the other or is it just a matter of price? Additionally, does chrome have an advantage in maintaining its shiny appearance?

When it comes to choosing between Nickel Boron and Chrome plating for a Bolt Carrier Group (BCG), there are some similarities to consider. Both coatings are incredibly slick, requiring little lubrication, and are easy to clean. However, there are some differences to keep in mind.

🔵 Nickel Boron is a corrosion-resistant coating that is highly durable and resistant to wear, making it an excellent choice for those who want to minimize the frequency of cleaning and maintenance. Additionally, it can withstand high temperatures and is suitable for use in both semi-automatic and automatic firearms.

🟢 Chrome plating, on the other hand, is more affordable than Nickel Boron and is also highly durable and resistant to wear. However, it is not as corrosion-resistant as Nickel Boron and is better suited for use in semi-automatic firearms.

Another difference is in the aesthetics of the coatings. While both are very slick, Chrome plating has a shiny appearance that lasts longer than Nickel Boron, which can discolor over time.

Ultimately, the choice between the two coatings will depend on the user’s specific needs and preferences, as well as their budget.

I am worried about chipping on the nickel carrier group.

While Nickel Boron coatings are generally very durable and resistant to wear, there is still a possibility of chipping or flaking, particularly if the coating was not applied correctly or if the BCG is exposed to excessive heat or abrasion.

🟡 Chipping or flaking of the Nickel Boron coating can result in reduced performance and may also cause reliability issues with the firearm. Therefore, it’s essential to inspect the BCG regularly for any signs of damage or wear and replace it if necessary to ensure proper function and safety.